used material

rectangle stainless steel tube 60x30mm, 1.5mm thickness

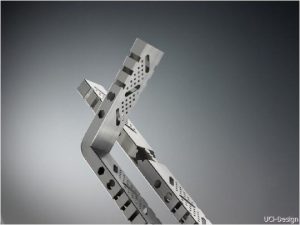

Application

manufacturing method to create a “swing-” chair.

Production

cutting ends below the edge radius, a piece in the middle is responsible for stability during the cutting process

Characteristics

Both pieces (left and right) were cut as one tube, they have then to be fold manually to get round edges. The inside tube edges are welded. All pieces are combined with special cutted round tubes – after “click” at both ends, they guarantee for stability.